Elevate Customer Service Satisfaction

Offer lightning-fast problem solving, eliminate costly unnecessary travel, and delight your customers with VSight.

VSight Remote

PROBLEM

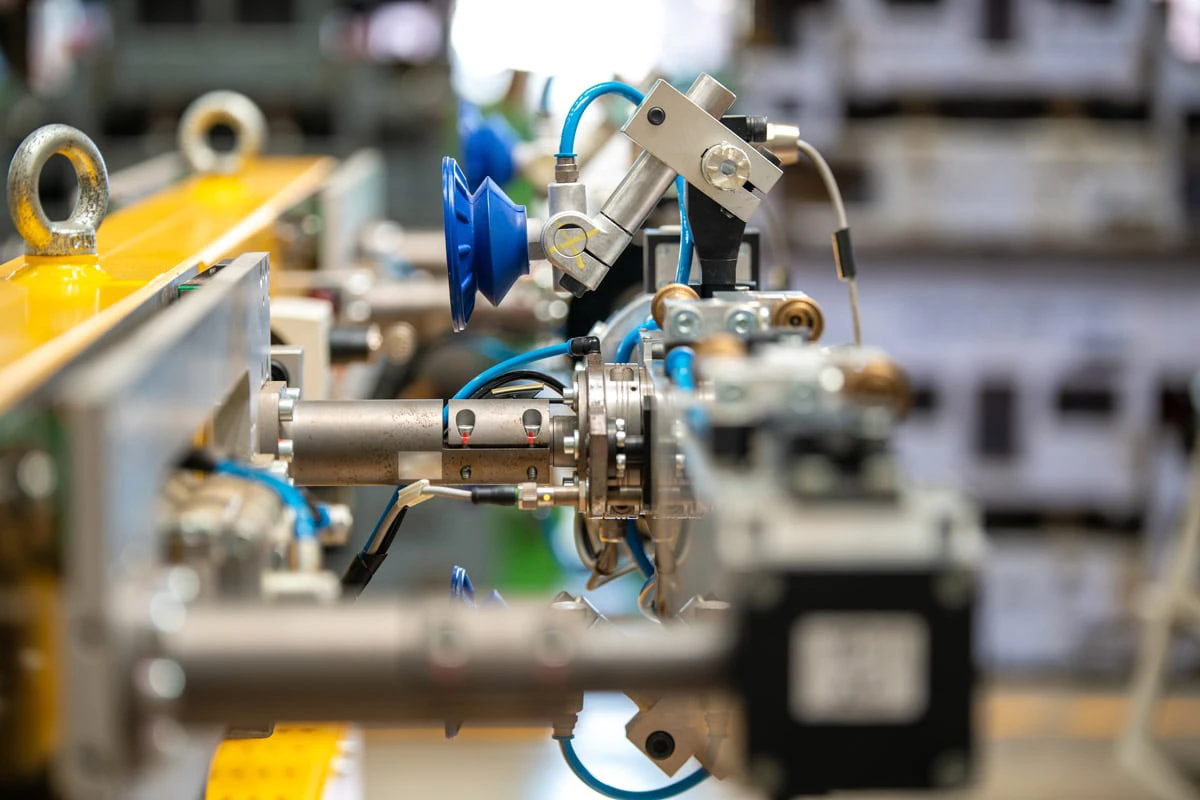

Companies that sell capital-intensive machinery and equipment share a common requirement: their end-customers expect a high level of service quality and availability. The expertise to service this equipment typically resides with the manufacturer, who often dispatches technicians to the customer’s site to address problems, perform repairs, overhauls, and maintenance tasks.

SOLUTION

With VSight Remote, machinery companies can minimize or eliminate the need for unnecessary travel. Oftentimes, it is essential to assess a problem before dispatching the appropriate technician to the site. Instead of relying on lengthy email exchanges, VSight Remote offers features such as snapshot collaboration, allowing service managers to annotate on a frozen image to accurately determine the appropriate expert for the issue at hand. Given the ubiquity of smartphones, many companies leverage VSight Remote on these devices, especially for minor issues.

ENHANCED SAFETY WITH HANDS-FREE SUPPORT: SMART GLASSES

Safety is a paramount concern at most worksites, and this is where the significant advantage of using smart glasses with VSight Remote becomes apparent. Technicians and customers can work hands-free while being connected through audio and video to an expert located remotely, allowing them to perform tasks with both hands. With LTE modems equipped with SIM cards on the glasses or by using a simple hotspot with smartphones, technicians can easily connect to the internet, ensuring seamless communication and collaboration with experts “back home.”

STABLE CONNECTIVITY IN REMOTE LOCATIONS: LOW BANDWIDTH REQUIREMENTS AND EASY GUEST ACCESS FOR END-CUSTOMER SUPPORT

The minimal bandwidth requirement of VSight Remote ensures a stable connection, even in remote locations. Additionally, with the easy accessibility of VSight Remote through guest links and QR codes, even those who are unfamiliar with the platform can quickly connect. As a result, many machinery and equipment customers of VSight utilize the system to provide remote support to their end-customers from their headquarters, eliminating the need for a service technician to be physically present. This allows for convenient and efficient support, benefiting both the company and its customers.

VSight Workflow

PROBLEM

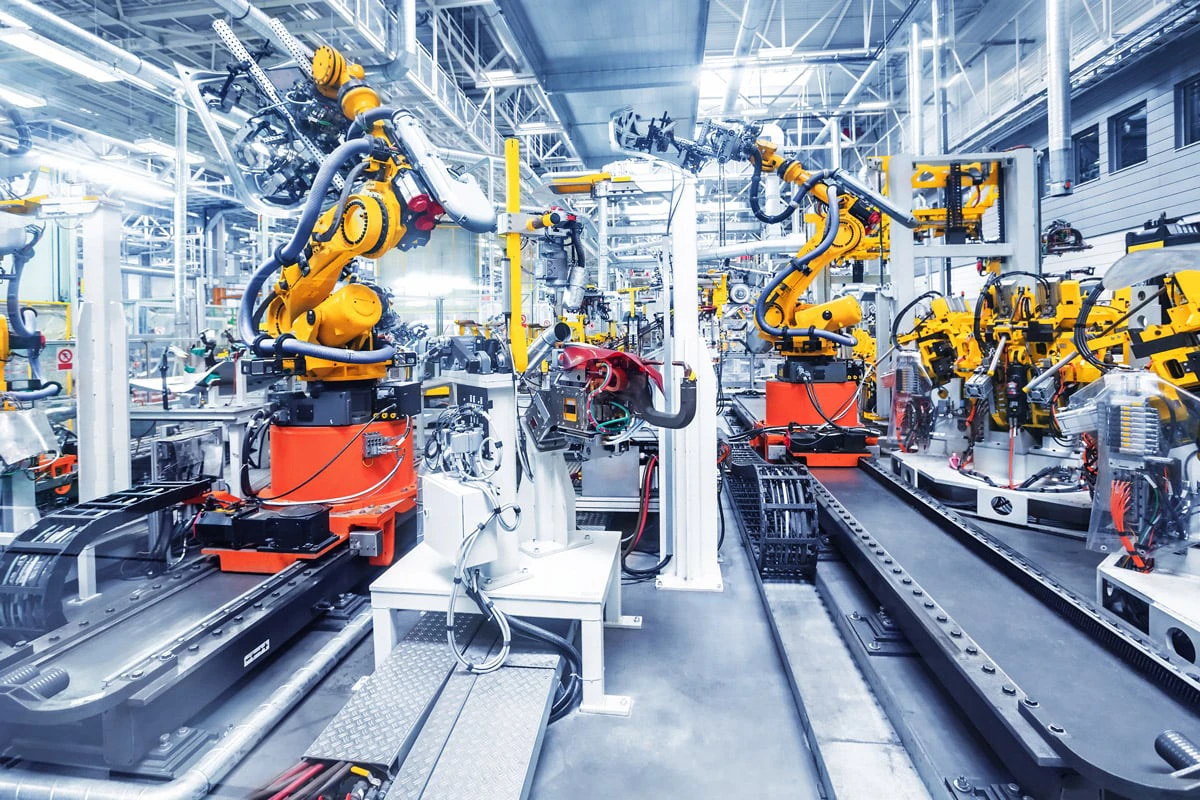

Machinery and equipment companies often employ a team of highly skilled service technicians who possess extensive expertise in their equipment. The nature of their capital-intensive and complex machinery requires detailed documentation of installation, commissioning, and ongoing maintenance, repair, and overhaul activities throughout the lifecycle of the equipment. This use case is relevant to various companies operating in similar industries, where meticulous documentation and technical expertise are crucial for ensuring the efficient operation of their machinery.

EFFICIENT FIELD DOCUMENTATION

VSight Workflow is utilized to document the work of field technicians, who carry tablets with them while on site. Every step of the process is meticulously documented using text fields, radio buttons, checklists, as well as pictures and videos, which are crucial for comprehensive reporting. Additionally, measurement values from various parts of the process and equipment performance are captured and incorporated into the reports, enriching the documentation and ensuring accurate and detailed records of the technicians’ work.

WORK IN OFFLINE MODE

Since many of the sites where the technicians work are situated in remote areas with limited internet connectivity, maintaining a stable internet connection can be challenging. However, with VSight Workflow, technicians have the flexibility to work in offline mode, capturing all the necessary data and creating reports on their tablets without requiring an internet connection. Once they regain internet access, the reports can be easily uploaded, ensuring that the documentation is complete and accurate, even in areas with limited connectivity. This feature enables seamless reporting and documentation, regardless of the availability of internet connectivity in remote locations.

SIGNING OFF: CONFIRMATION OF SERVICE COMPLETION AT THE CUSTOMER’S SITE

At the conclusion of their service intervention, before leaving the customer’s site, the technicians can sign the completed report on the touchscreen of their tablets. Similarly, their counterparts from the customer’s side can also sign the report on the tablet to confirm the work performed. This digital signature process ensures mutual agreement and confirmation of the services rendered, providing a transparent and efficient way to validate the work performed by both parties. This streamlined process eliminates the need for paper-based signatures and facilitates efficient documentation and confirmation of service interventions.

SECURE DOCUMENTATION AND REPORTING

All the steps of the workflow, along with the captured data, pictures, and signatures, are securely stored on a server based in Europe. This ensures that the information is safely preserved and can be accessed at any time for future training and documentation purposes. The European-based server adheres to strict security standards, ensuring the confidentiality and integrity of the stored data. This enables the company to maintain a comprehensive and secure repository of service interventions, facilitating efficient training, documentation, and analysis of past work for continuous improvement and knowledge sharing.

Agramkow Elevates Service Quality & Customer Satisfaction

Watch and learn why Agramkow chose VSight, discover how it significantly enhances customer satisfaction and operational efficiency throughout their organization.

Explore Other Industries That VSight Empowers

Learn more about VSight

See how VSight can help you with your field service, maintenance, onboarding and training operations.